Inspection

Whether you need a first article inspection of a new production part, a scan of a complex turbine blade for an end of life wear inspection, or a fully automated GD&T report for every part that comes off the line, NextGen Metrology has the equipment and know how to be your one-stop shop for any of your inspection needs.

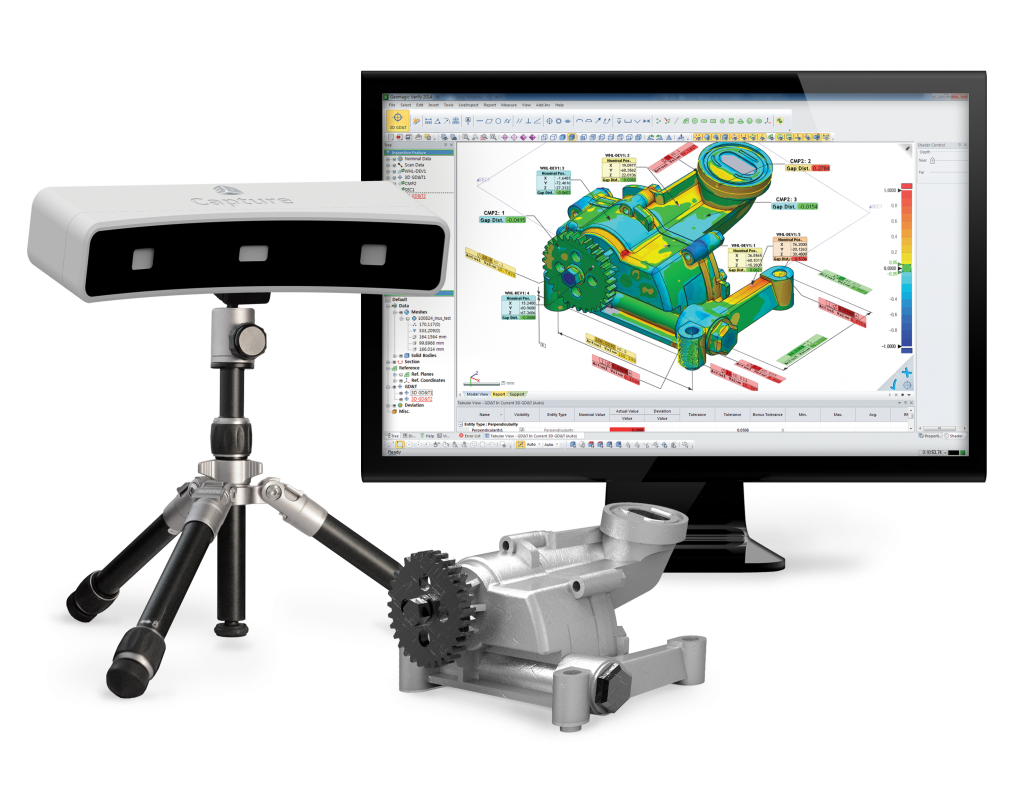

Part Inspection is the process of taking measurements from a physical part and comparing them to a nominal “as designed” drawing or model. As the scanning and measurement tools have matured, the ability to quickly collected millions of points of measurement have completely changed the way we are able to create inspection reports.

Now, a color map deviation report allows a quick glance over the parts to ensure that everything is “in the green.” Maximum deviation amounts can be entered, so that only points that exceed that amount will be shown in varying colors, depending on if the part is above or below the accepted standard. Detailed 2D analysis can be given in a cross-section analysis report. Geometric Dimensioning and Tolerancing (GD&T) reports are excellent at repeatedly checking for geometric shapes, angles, thickness and concentricity. Specialized custom reports can also be created to suit whatever is needed to ensure that the part is exactly as intended for its application. Whether it be just one part or every part on the production line, a quality inspection using 3D scans can be adapted to fit almost any need.