Reverse Engineering

Whether your goal is to make engineering models of an already existing production part, or create a model to mate a newly designed part to an already existing part, NextGen Metrology has the equipment and the know how to be your one-stop shop for any of your reverse engineering needs.

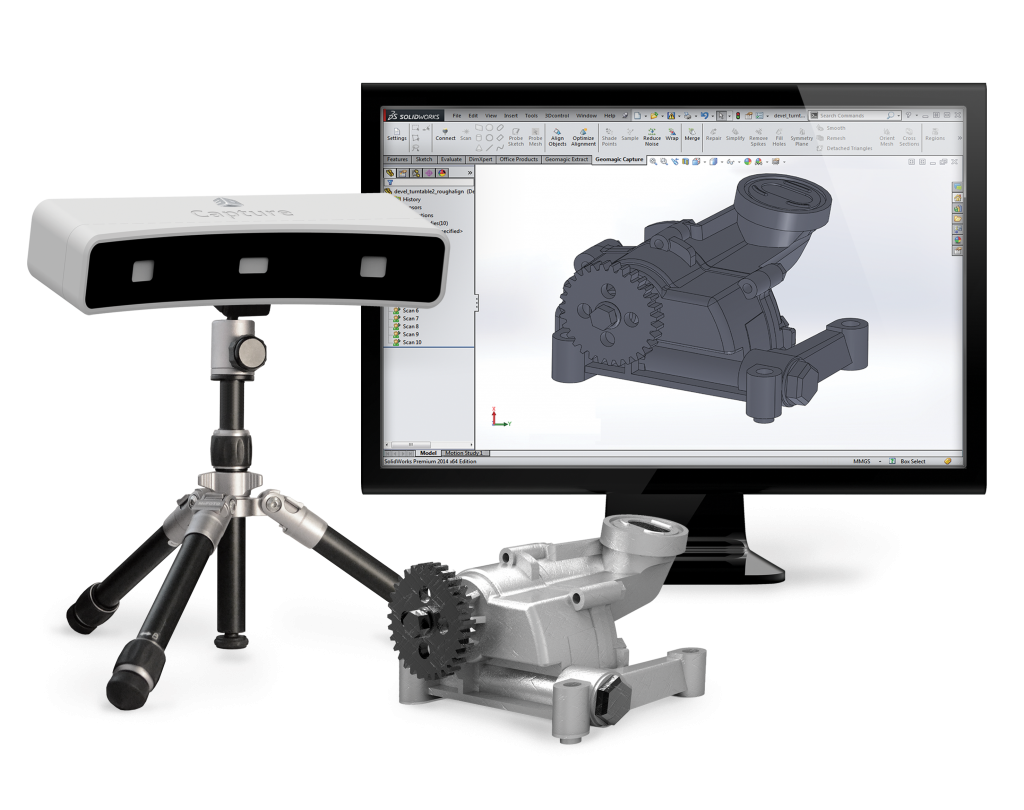

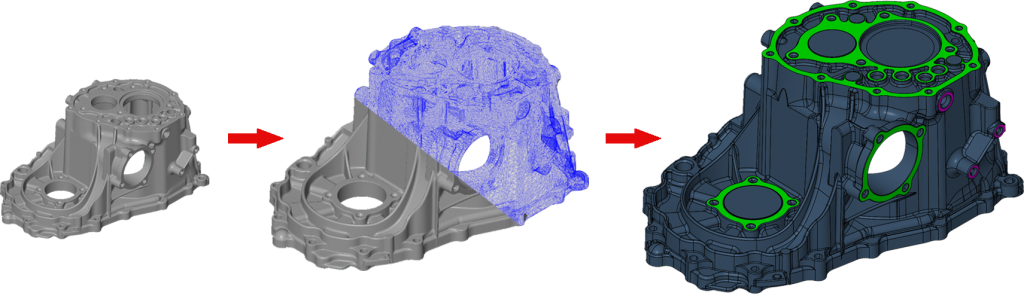

Reverse engineering is the process of creating a digital CAD model from an existing physical part. The typical process starts with a quality 3D scan. Once the scan is complete, the point cloud is imported into specialized CAD software. Depending on the complexity of the part, the tech modeling the part could spend hours, or even days carefully recreating each feature. Once the model is complete, it can be transferred to almost any of the popular 3D CAD software packages on the market.

Reverse engineering is the area of service the separates the decent metrology companies from the great ones. It requires the most hands-on experience and knowledge to do correctly. In many ways it is much more difficult than designing a model from scratch. With input from the client, the tech must interpret the original design intent and nominalize the measurements of the original part.

Another key point that sets our service apart from others is the formats that we output the files in. The traditional method is to just export the file in a neutral file format such as STEP or IGES. These are considered “dumb” solids, and while they do maintain the dimensional accuracy of a native format, they are not editable the way that a model with a fully parametric feature tree would. We can output native fully parametric model in any number of software packages such as Solidworks, Inventor, Catia, Solidedge, Etc. Using this method, the model you receive would be just as if you have designed the part from scratch inside your favorite modeling package.

Our diverse CAD capabilities include but are not limited to:

- Producing IGS and STP CAD models of any shape and size.

- Providing native CAD files in Solidworks 2013 and later, Inventor 2012 and later, Siemens NX, Catia V5 and V6, and Pro E Creo.

- Providing 2d drawings for fabrication, sheet metal bending, machining, welding, injection molding, blow molding, etc…

- Providing 3d assemblies models for large and small assemblies.

- Providing design and modification services to achieve end goals.